Tattio

Issue: XXIII.5 September + October 2016Page: 14

Digital Citation

Authors:

Cindy Kao, Paul Johns, Asta Roseway, Mary Czerwinski

Describe what you made. Tattio is a fabrication process for creating on-skin interfaces inspired by the aesthetics of existing body art such as metallic jewelry-like temporary tattoos. The process allows you to generate functional components such as NFC tags while retaining the aesthetics and user experience of existing metallic temporary tattoos. Tattio is low cost and user-friendly; we seek to enable individuals to design, make, and wear their own on-skin creations.

Briefly describe the process. The Tattio fabrication process consists of three main building blocks.

Sketching. Users can sketch the skin circuitry of their choice with graphic design software.

|

Sketching skin circuitry with graphic design software. |

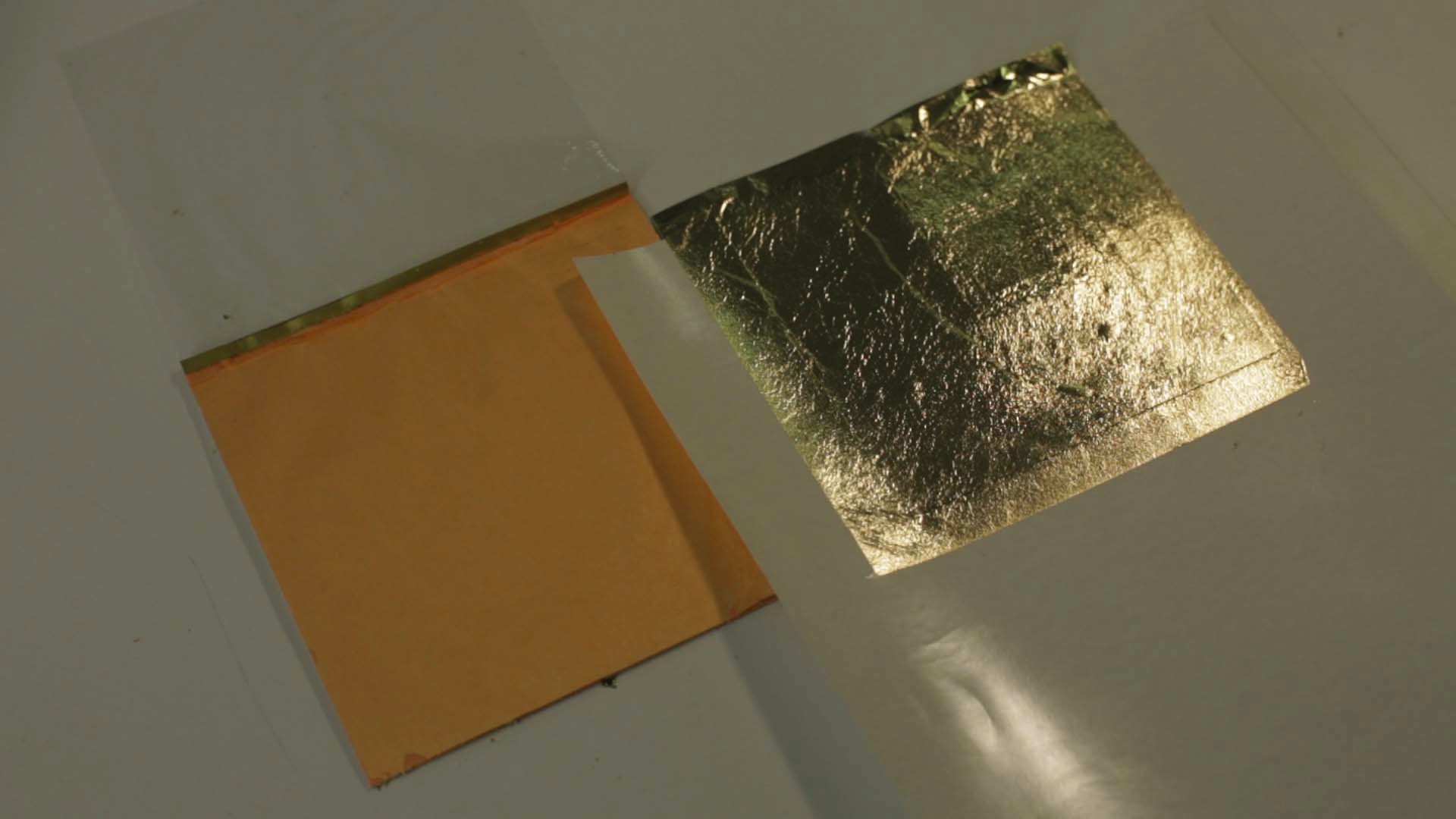

Fabrication. Tattio builds on a flexible-circuit manufacturing process with gold leaf as the conductive material and thin tattoo-paper silicon as the flexible substrate that adheres to the skin. (During a traditional flexible-circuit manufacturing process, thin copper foil is machine-cut into circuit traces and layered onto flexible Kapton backing to create conductive traces on flexible materials.) The fabrication process comprises three parts: First, we create a stencil for the circuitry by applying a layer of vinyl film on the thin tattoo paper and cutting the film layer with a low-cost vinyl cutter. A stencil on tattoo paper results from the positives of the cut film layer. After creating the stencil, we layer gold leaf on top to create conductive traces by applying spray adhesive onto tattoo paper and stacking multiple layers of gold leaf. Then we remove the remaining negatives of the film layer, which leaves the conductive gold-leaf traces. Finally, we attach surface-mount electronics to the gold leaf traces by through-holing the tattoo paper, fix all electronics in place through the holes, and secure them to the metal leaf traces with a small piece of conductive fabric tape. We then add a layer of thin tattoo paper adhesive for adhering to skin.

|

Cutting the vinyl film layer. |

Application on skin. We apply the fabricated components to the skin through water transfer, similar to applying temporary tattoos.

|

Creating a stencil of the circuitry. |

What materials and tools did you use? The key fabrication material is gold leaf. Repurposed from traditional craft practices of gold-leaf furniture gilding, gold leaf is also widely used in food and cosmetics for applications on or close to the body. After several material experiments, we selected gold leaf because it is conductive, skin-safe, easy to attach to and remove from the skin, and clean. Gold leaf also withstands movements and skin deformations during motion. Finally, the appearance of gold leaf resembles jewelry, making it a good aesthetic choice for our project.

|

Applying gold leaf as the conductive material. |

What is the one thing about making this that you would like to share with other makers? We envision the future of on-skin interfaces will converge toward the aesthetics of existing body art, becoming more seamlessly integrated with our bodies and more appealing for everyday wear. Tattio is a fabrication process we created to explore this possible future.

|

Mounting electronics. |

|

Applying the Tattio device to the user's skin through water transfer. |

Cindy Hsin-Liu Kao, MIT Media Lab, [email protected]

Paul Johns, Microsoft Research, [email protected]

Asta Roseway, Microsoft Research, [email protected]

Mary Czerwinski, Microsoft Research, [email protected]

Copyright held by authors

The Digital Library is published by the Association for Computing Machinery. Copyright © 2016 ACM, Inc.